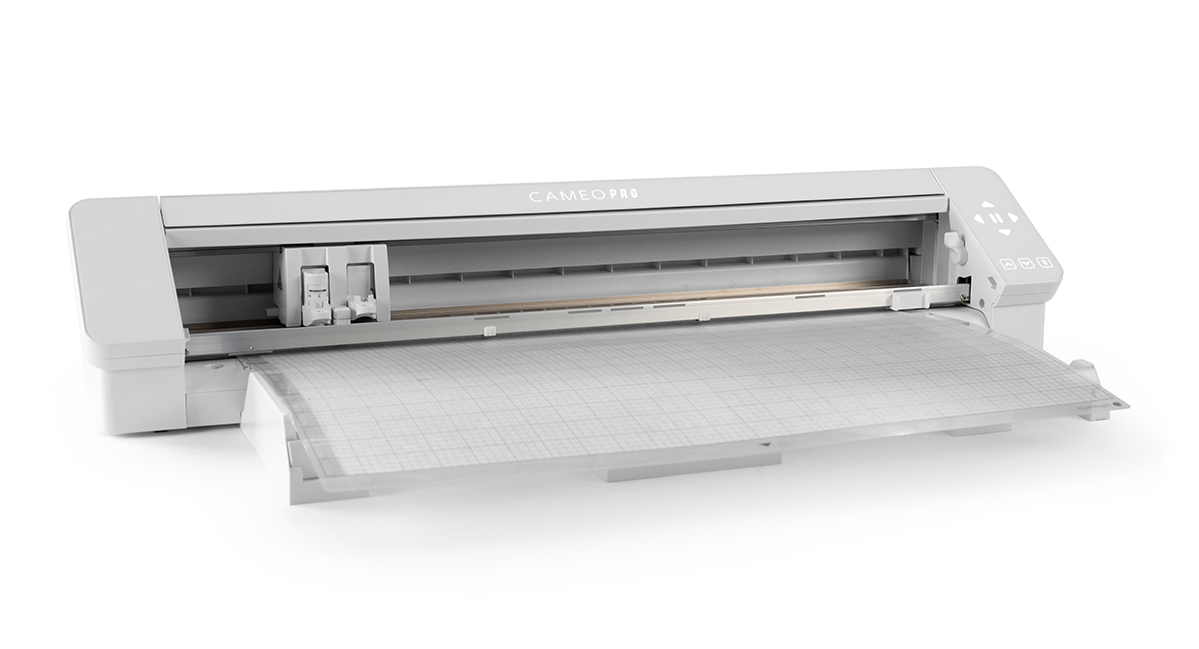

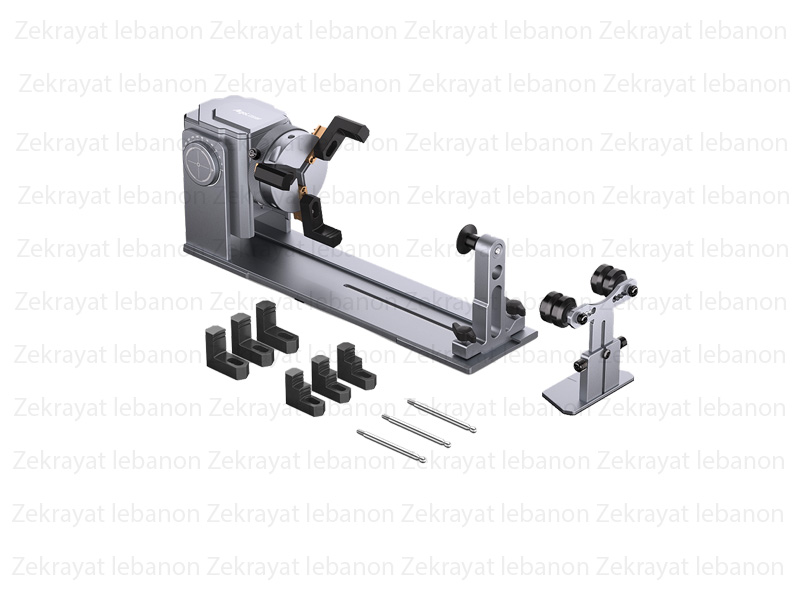

60 CM DTF 3 Print Heads

- - itemNo. 3003

- - Features.

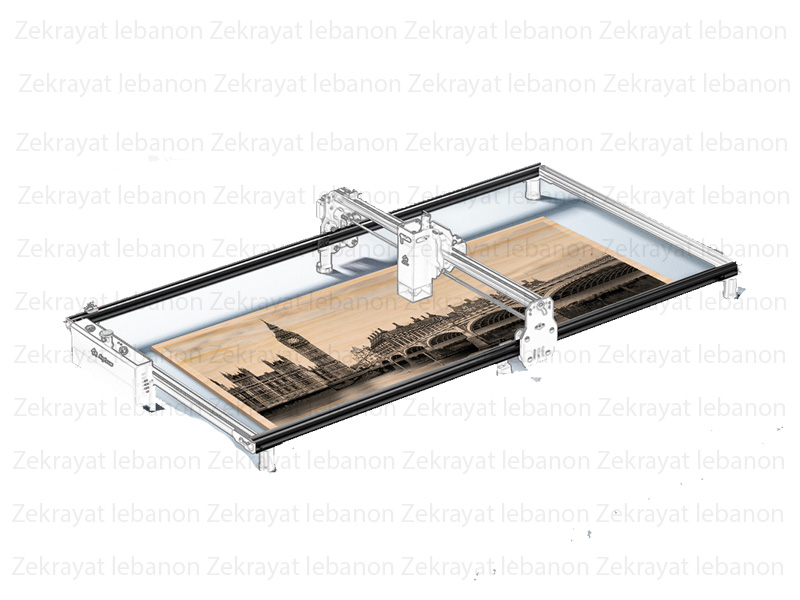

60cm DTF printer(with Interweave printing program)

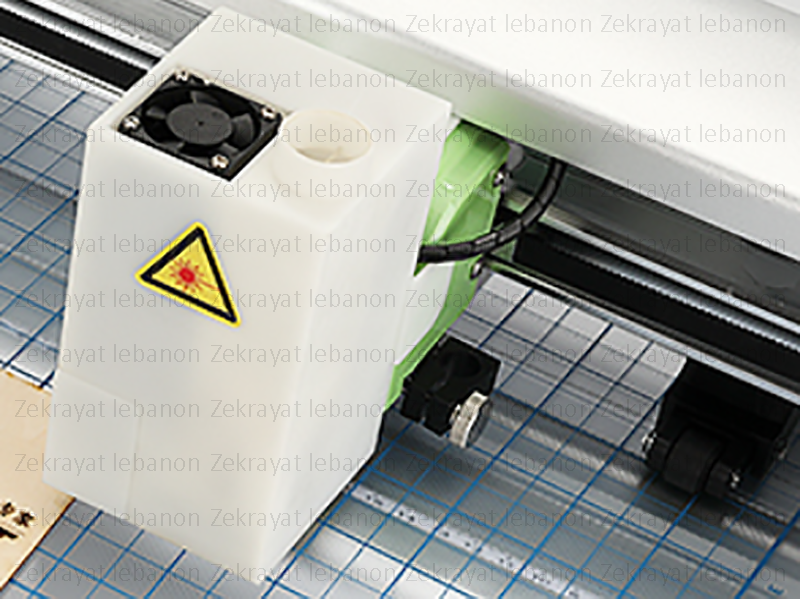

Nozzle Type:

1 original Epson I3200

2 original Epson I1600

Printing Speed:

4 pass 720*1200: High speed mode 24m*/hour

6 pass 720*1800: HD mode 18m*/hour

Color Mode(2 options)

СМУК+W or CMYK+LC+ LM+LY+LK+W

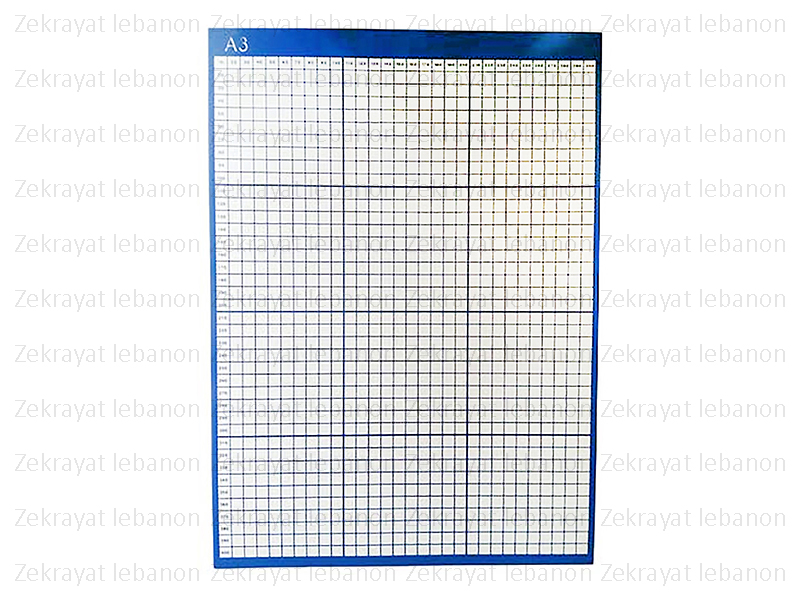

Print Format: 600mm-650mm

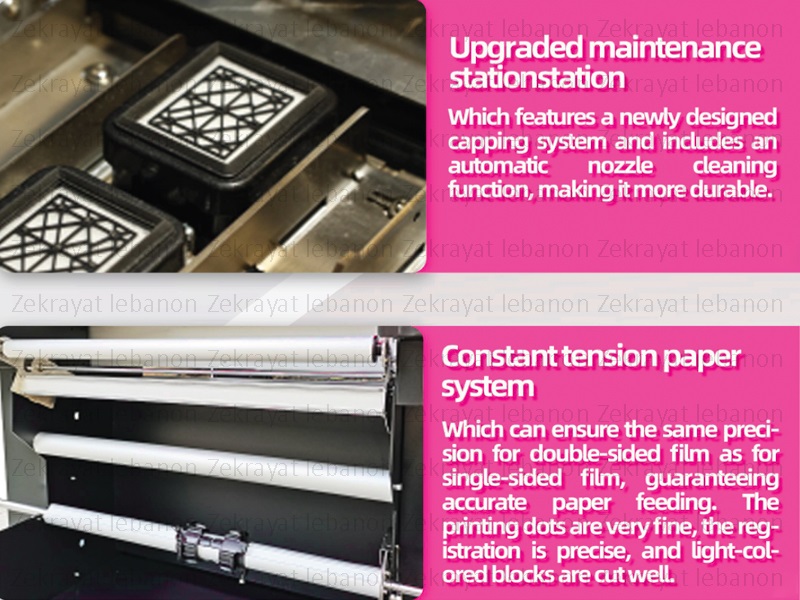

Media Transfer: Damping paper/tension paper

Heating Equipment: Front, middle and back three-stage heating

Power Supply: 110V/220V 50-60Hz

Power: 1kw

Working Environment: Temperature 20-28 © Humidity 70%

Ink road system: Automatic ink supply, Constant pressure circulation system

Weight: 272KG60cm Powder Shaker

Power= 2KW

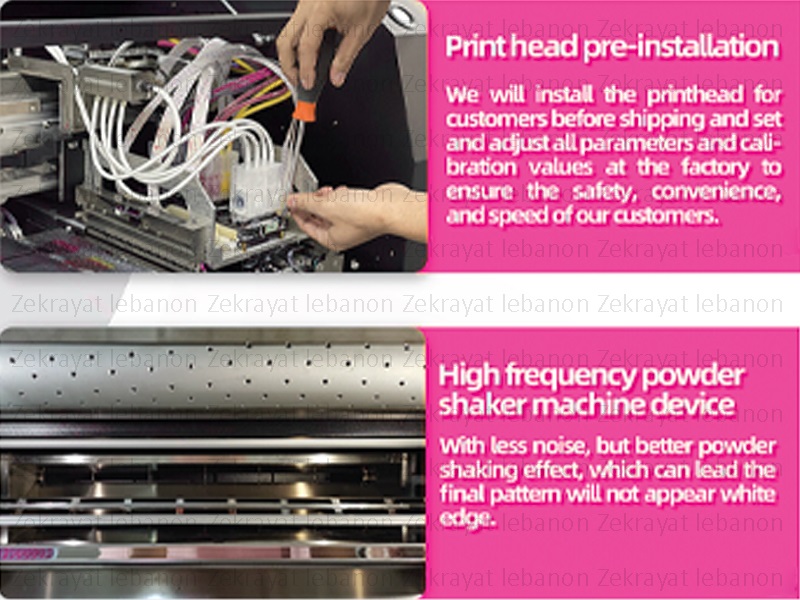

Shaking Powder: Motor vibration, automatic powder return-free

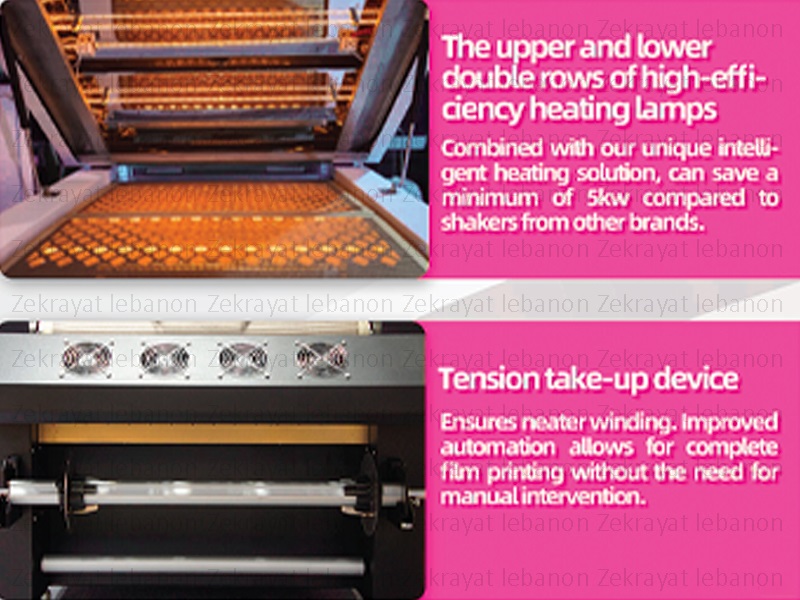

Heating Method: Back baking and front baking Fast constant temperature heating

Take-up and Feed Film: Constant tension automatic induction system

Operation Mode: Manual control/Auto control

Mesh Belt: Drum suction operation mesh belt

Automatic Deceleration of Film Cutting: Prevent deformation of heating film

Method of Dusting: Constant weight automatic sensing

Machine Weight: 240KG

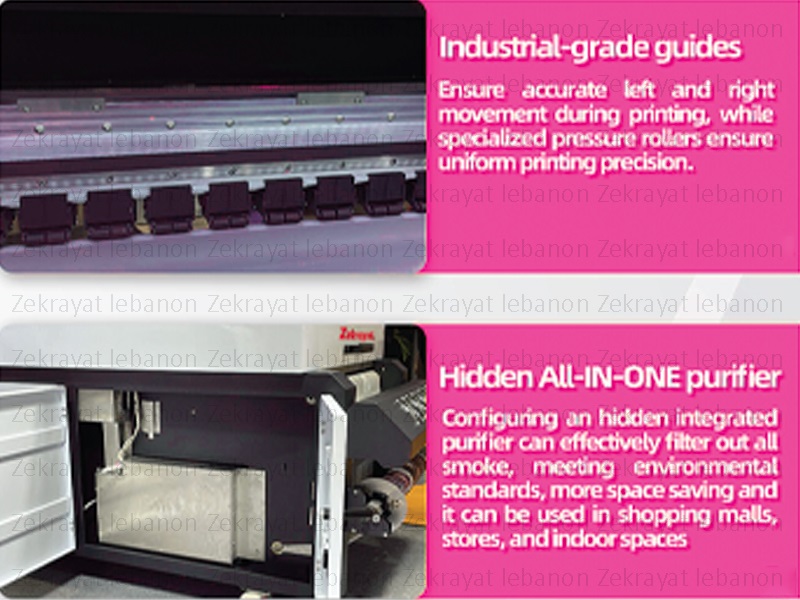

Configuration: With All-in-one smoke purifierTOTAL PRINTER WITH SHAKE MACHINE

Cover Area

108*350cm

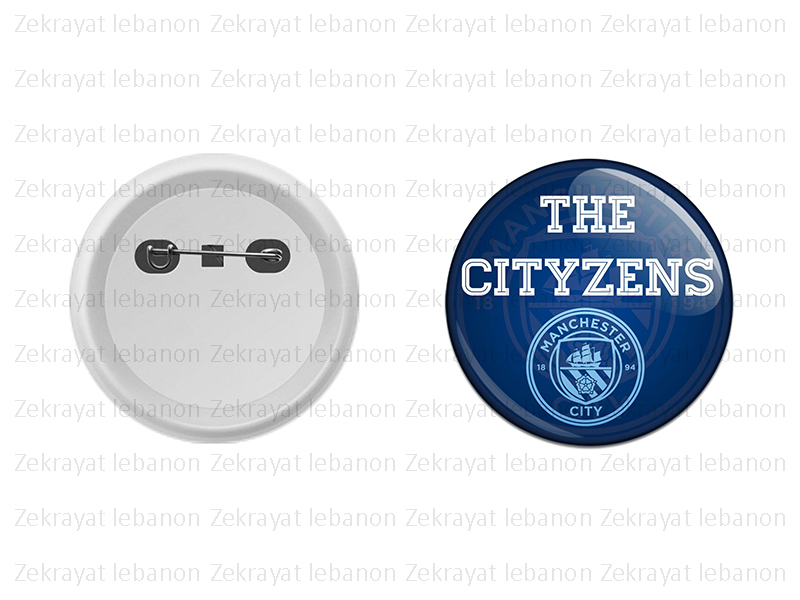

| Category: | Textile DTF |

| Product Code: | 3003 |

Our machines employ an intelligent heating solution with patented technology, allowing us to save over 5KW of power compared to other factory machines.

Our patented automatic mode enables a single operator to control three machines simultaneously. This translates to significant monthly savings in electricity costs and labor wages, potentially allowing you to acquire an additional new printer.

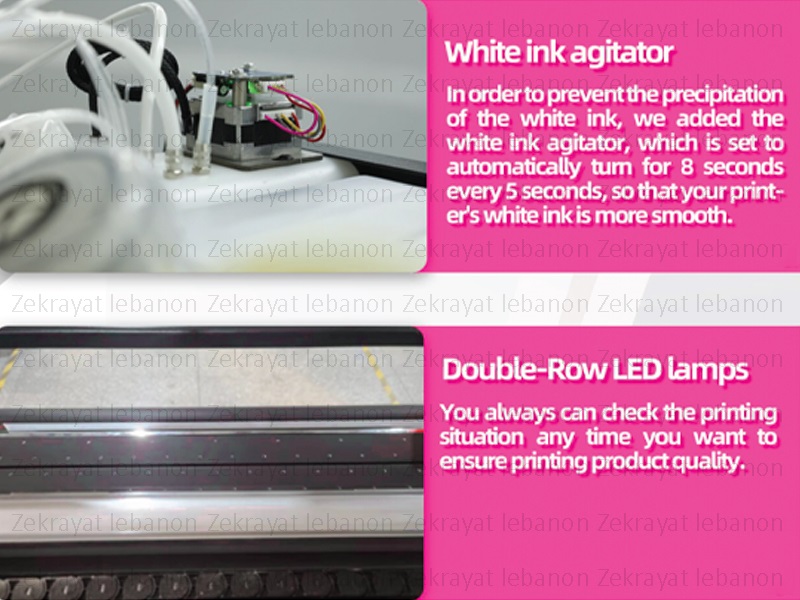

White ink circulation

The cycle speed is automatically adjusted, and the white ink circulation is automatically regulated based on printing or idle conditions, unaffected by temperature. During idle periods, the white ink circulates slowly to prevent settling, thus extending the lifespan of the filters and nozzle filters. During printing, the white ink circulation accelerates to ensure a stable ink supply.

Eng

Eng

.jpg)

.jpg)

.jpg)

.jpg)